T8 Tube Light Socket G13 Lamp holder T8 fluorescent Lamp holder T8 fluorescent light socket G13 lamp Socket BASE.

G13 lamp holder End fixing lamp holders

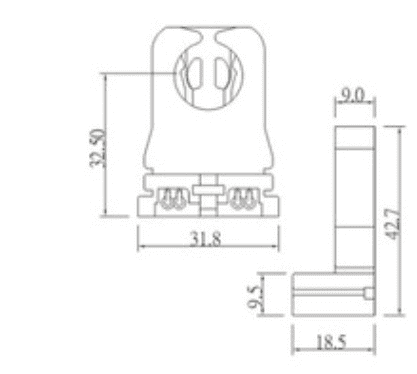

-Thickness 9.5mm

-Snap in pins with/without spring

-PC body, Phosphor bronze contacts, stainless spring

-Wt.6g/5g/9.8g, Pkg.500pcs/500pcs/250pcs

-Rated temperature: T130/Tm110

-For wall thickness: 0.6-1.1 mm

-Push wire terminals 2 holes: 0.5-1 mm2

G13 lamp holder Packaging & Delivery

Packaging Details: 44*38.5*33/carton

Delivery Detail: Within 14 days after payment.

1. fluorescent lamp holder g13: 22.7mm/26.7mm

2. housing: PC

3. rotor: PBT/PC

4. contacts: phosphor bronze

Specification of G13 lamp holder.

Weight: 9g

Material: PC(Body)+Phosphor bronze (Conduct Contact)

Certification: CE&CQC

Maximum permissible temperature at the rear of the lamp holder: 110 degrees.

Rating: 500V;2A

High Quality cultus Listed T8 T10 G13 lamp holder 660W 1000V

Rating :600V 600W(UL) 250V 2A (CQC, VDE)

Material: plastic

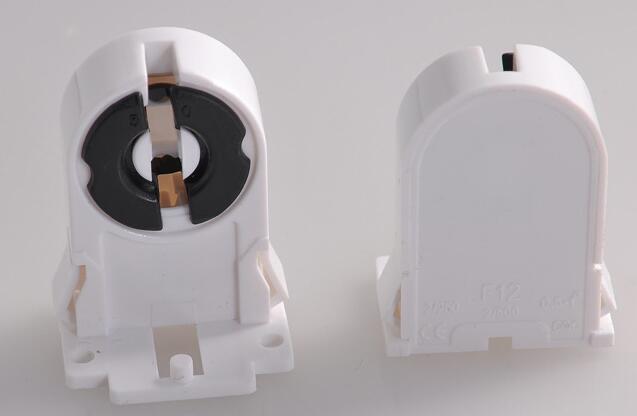

Lamp base: G13

Available color: white

PS. : CQC, CE, VDE, UL&CUL.

What is a T8 fluorescent light socket?

A T8 fluorescent light socket is a type of electrical connector that is used to connect T8 fluorescent bulbs to the electrical circuit. The sockets have a bi-pin design and are typically made of ceramic or plastic materials. They are designed to accommodate the 1-inch diameter of T8 bulbs and are compatible with electronic ballasts that regulate the current flow to the bulb.

T8 fluorescent light sockets are widely used in commercial and industrial lighting applications due to their high energy efficiency, long lifespan, and low maintenance requirements.

T8 fluorescent light sockets come in a variety of designs and configurations, including shunted and non-shunted sockets.

Shunted sockets are used with rapid-start ballasts and have a jumper wire that connects the two pins of the socket.

Non-shunted sockets, on the other hand, are used with instant-start ballasts and have separate terminals for each pin of the socket. It is important to choose the right type of socket for your specific lighting application to ensure proper functioning and avoid potential safety hazards.

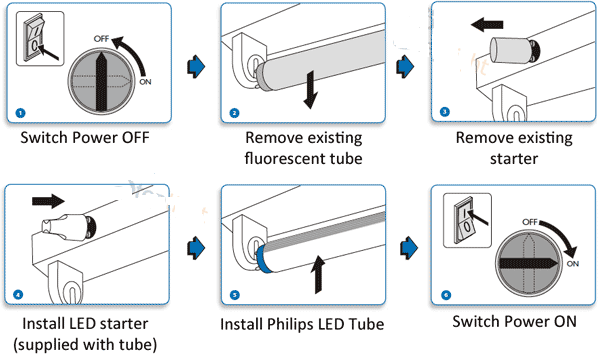

How do you install a T8 fluorescent lamp holder?

Based on my experience, installing a T8 fluorescent light lamp holder is a relatively simple process that can be done with basic tools and some electrical knowledge.

The first step is to turn off the power to the circuit that you will be working on.

Then, remove the old socket by twisting it counterclockwise and pulling it out of the fixture.

Next, insert the wires into the terminals of the new socket, making sure to match the wire colors to the correct terminals. The wiring diagram for the socket should be included with the new socket or available online. After the wires are securely connected, insert the new socket into the fixture by twisting it clockwise. Make sure the socket is aligned properly and securely in place.

Finally, replace the fluorescent bulb and turn on the power to the circuit to test the new socket.

What is the difference between T8 and T12 fluorescent sockets?

The main difference between T8 and T12 fluorescent light sockets is their size and compatibility with different ballasts. T8 sockets are designed to accommodate 1-inch diameter T8 bulbs, while T12 sockets are designed for 1.5-inch diameter T12 bulbs.

T8 bulbs are more energy-efficient and have a longer lifespan than T12 bulbs, which is why T8 lighting has become more popular in recent years.

Another difference is the type of ballasts that T8 and T12 bulbs require. T8 bulbs are typically used with electronic ballasts, which are more energy-efficient and provide better control over the current flow to the bulb.

T12 bulbs, on the other hand, are usually used with magnetic ballasts, which are less efficient and have a shorter lifespan than electronic ballasts. It is important to choose the right socket and ballast for your specific lighting application to ensure optimal performance and energy efficiency.

Can T8 fluorescent light sockets be replaced with LED sockets?

Yes, T8 fluorescent light sockets can be replaced with LED sockets, but it requires some modifications to the wiring and the ballast. LED bulbs require a different type of driver than fluorescent bulbs, and most LED bulbs are designed to work with a direct-wire connection rather than a ballast.

Therefore, in order to replace T8 fluorescent bulbs with LED bulbs, you will need to remove the existing ballast and rewire the sockets for direct-wire connections.

The sockets are also retrofit kits available that can make the process of replacing T8 fluorescent bulbs with LED bulbs easier. These kits typically include new sockets, LED bulbs, and a driver that can be connected directly to the electrical circuit.

Retrofitting your existing T8 fluorescent lighting fixtures with LED bulbs can provide numerous benefits, such as improved energy efficiency, longer lifespan, and reduced maintenance requirements. LED bulbs also emit less heat than fluorescent bulbs, which can help to reduce cooling costs in hot environments.

Before attempting to retrofit your T8 fluorescent lighting fixtures with LED bulbs, it is important to check with the manufacturer or a qualified electrician to ensure that the retrofit kit is compatible with your specific lighting fixture and wiring.