Knowing how much weight a light bulb socket can hold is important for safety and practicality. You don’t want to blow something up, damage the fixture, or hurt someone because you didn’t know how much weight the socket could hold. Most common light bulb sockets can hold between 10 and 15 pounds. The exact amount depends on the type of socket, what it is made out of, and how it’s installed.

The weight a light bulb socket can support is primarily influenced by its material, the type of fixture it’s part of, and the overall design. Porcelain sockets, for instance, are generally more durable than plastic ones and can handle greater loads without risk of cracking or overheating. Metal sockets offer excellent strength but are often limited by the supporting structure rather than the socket itself. In ceiling-mounted or hanging fixtures, the structural support and mounting hardware play a crucial role in determining how much weight the socket can safely bear.

Factors That Determine Weight Capacity

The material of the socket is a key factor in its load-bearing capacity. Porcelain sockets, commonly used in industrial and high-wattage fixtures, are known for their durability and heat resistance. These sockets are ideal for applications requiring heavier accessories. Plastic sockets, though lightweight and cost-effective, are more prone to deformation or damage under stress. Metal sockets, often used in outdoor or heavy-duty fixtures, combine excellent strength and durability.

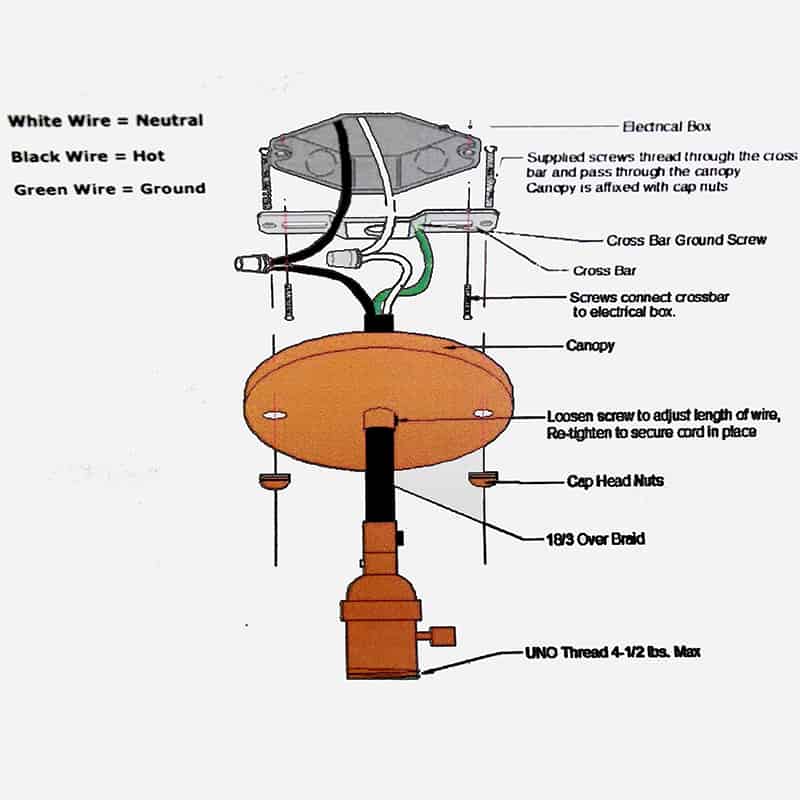

The type of fixture also affects weight limits. Ceiling-mounted sockets often rely on brackets or reinforcements to support weight, while wall-mounted fixtures may have lower capacities due to their orientation. Hanging fixtures, such as pendant lights, often include a cord and hook that distribute weight, ensuring the socket itself isn’t overloaded.

Typical Weight Capacities of Light Bulb Sockets

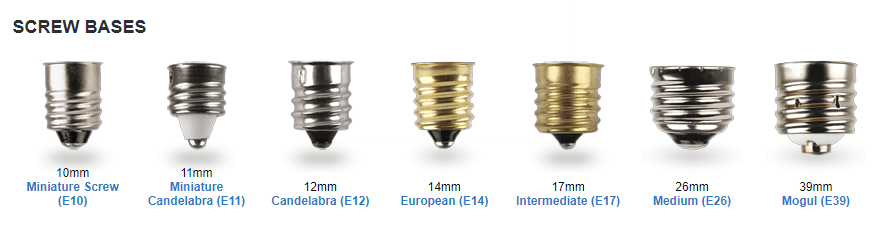

Standard E26 and E27 sockets, the most common in residential and commercial settings, are designed to hold light bulbs and lightweight accessories up to 10-15 pounds. These capacities make them suitable for most household applications, such as installing LED or incandescent bulbs. Specialized sockets, like the larger E40 models, are designed for industrial use and can support heavier loads, including high-intensity discharge lamps or heavy-duty fixtures.

Hanging fixtures, such as pendant lights, introduce another consideration. The weight capacity often depends on the strength of the cord and hook in addition to the socket itself. Most cords are rated to support loads similar to the socket’s capacity, but always check the specifications to avoid exceeding the limit.

Safety Considerations When Adding Weight

Ensuring electrical and structural safety is paramount when dealing with weight-bearing sockets. Exceeding the recommended weight limit can lead to sagging fixtures, overheating, or electrical connection failure. Additionally, the environment where the socket is installed can affect its performance. For instance, sockets in moist or humid areas may degrade faster, reducing their capacity to hold weight. Always consider the socket’s IP rating to determine its suitability for such conditions.

Avoiding overloading is critical. If a fixture shows signs of strain—such as a loose fit or visible sagging—it’s essential to reduce the load or reinforce the structure. Using lighter bulbs or removing additional accessories can help maintain the socket’s integrity.

Common Applications and Weight Management

Light bulb sockets are used in a wide range of applications, from decorative to industrial. Decorative applications often involve lightweight items such as paper lanterns or shades, which typically fall well within the socket’s weight limits. Industrial uses, on the other hand, may require sockets that can support heavier loads, such as large lamps or fixtures in warehouses.

Socket adapters and extenders can also influence weight capacity. While these accessories provide flexibility, they may reduce the overall strength of the setup. For instance, a B22-to-E27 adapter can enable the use of different bulb types, but adding weight through extensions can put additional strain on the socket.

How to Test a Light Bulb Socket’s Weight Capacity

Manufacturer specifications are the best starting point for determining a socket’s weight capacity. Always refer to the product manual or label to identify weight and load limits. If this information isn’t available, practical testing can be done cautiously. Begin by attaching lighter objects and gradually increasing the weight while monitoring for signs of strain.

For larger or more complex installations, consult a professional. An electrician or structural engineer can assess whether a socket or fixture can handle specific loads, ensuring safety and compliance with local regulations.

Alternatives for Heavier Loads

If a light bulb socket cannot support the desired weight, there are alternatives. Reinforced fixtures, designed specifically for heavier loads, are an excellent choice for industrial or outdoor applications. Additionally, separate mounting solutions such as hooks or brackets can distribute weight more effectively, reducing the strain on the socket.

Another option is to design the setup with distributed loads. Instead of relying on a single socket, multiple fixtures can share the weight, creating a balanced and safer configuration.

Maintenance Tips for Weight-Bearing Sockets

Regular maintenance ensures the longevity and safety of weight-bearing sockets. Inspect the socket for cracks, wear, or loose connections. Addressing these issues early can prevent more significant problems. Cleaning the socket contacts periodically helps maintain good electrical conductivity and reduces the risk of overheating.

If a socket shows signs of damage or strain, replace it promptly. Using a damaged socket increases the risk of electrical failure or fire, especially under heavy loads.

Final Words:

The weight capacity of a lamp holder typically ranges from 10 to 15 pounds, depending on the material, fixture type, and design. By understanding these factors and following safety guidelines, you can confidently choose and maintain sockets for your lighting needs. Always prioritize manufacturer specifications, proper testing, and regular maintenance to ensure safe and effective lighting.